When it comes to the thrill of flight, there’s a hidden hero behind the scenes that often goes unnoticed—the engine. Among them, Rotax engines stand out as iconic powerhouses, fueling everything from small aircraft and ultralights to go-karts and snowmobiles. Curious about what makes these engines so special?

In this blog post, we’ll dive deep into the world of Rotax engines, unraveling their engineering marvels and exploring how they’ve become synonymous with reliability and performance in aviation. Buckle up as we embark on a journey through technology, innovation, and the exhilarating experience of soaring through the skies!

Introduction to Rotax engines

When it comes to aviation, the heart of many flight machines lies in a remarkable piece of engineering: the Rotax engine. These engines have carved out a niche for themselves in the skies, powering everything from light sport aircraft to gliders and even drones. But what makes them so special? As we dive into the fascinating world of Rotax engines, we’ll uncover their rich history, impressive technology, and why they have become a favorite among pilots and enthusiasts alike. Buckle up as we take you on an exciting journey through the ins and outs of these extraordinary powerhouses!

History and development of Rotax engines

Rotax engines have a rich history that traces back to 1920 in Austria. Initially, the company focused on manufacturing motorcycle engines, but their vision expanded over time.

In the mid-1950s, Rotax began venturing into aviation with its first aircraft engine. This marked a pivotal shift toward producing powerplants specifically designed for flight machines.

The introduction of lightweight and reliable two-stroke engines in the 1970s revolutionized general aviation. These innovations caught the attention of enthusiasts and manufacturers alike.

As technology advanced, Rotax embraced four-stroke designs in the late 1990s. This transition allowed them to meet stringent emissions standards while enhancing performance.

Today, Rotax is recognized globally for its continuous innovation and commitment to quality. The brand’s dedication fuels not only small aircraft but also ultralights and light sport planes across various markets.

How Rotax engines work

Rotax engines are known for their innovative design and efficiency. At the heart of these powerhouses is a two-stroke or four-stroke engine configuration. This allows them to deliver impressive performance while keeping weight to a minimum.

The internal combustion process begins when air and fuel mix in the cylinder. A spark ignites this mixture, creating an explosion that drives the piston downward. The rotational motion generated turns the crankshaft, which ultimately powers the propeller.

What sets Rotax apart is its use of advanced technologies like electronic fuel injection and liquid cooling systems. These features enhance fuel efficiency and reduce emissions significantly.

Moreover, many Rotax models come with variable speed capabilities, adapting seamlessly to different flight conditions. The result? Smooth and reliable operation under various circumstances, making them ideal for recreational aviation enthusiasts as well as commercial applications.

Applications of Rotax engines in aviation

Rotax engines have carved out a significant niche in the aviation world. Their lightweight design and high power-to-weight ratio make them ideal for various aircraft types.

Light-sport aircraft frequently rely on Rotax engines for their efficiency and reliability. These engines provide the necessary thrust while keeping fuel consumption low, which is crucial for recreational flying.

In addition to light-sport applications, many ultralight and experimental aircraft incorporate Rotax technology. Builders appreciate how these engines can be customized to suit specific needs, offering flexibility in performance characteristics.

Helicopters also benefit from Rotax’s innovative engineering. The smooth operation of these engines enhances stability during flight, making them popular among hobbyists and professionals alike.

Moreover, manufacturers are increasingly choosing Rotax for electric hybrid systems. This adaptation signals a forward-thinking approach toward sustainable aviation practices without sacrificing performance or reliability.

Advantages of using Rotax engines in flight machines

Rotax engines are renowned for their lightweight design. This characteristic enhances the performance of flight machines, making them agile and efficient in the air.

Fuel efficiency is another significant advantage. These engines often consume less fuel compared to traditional alternatives, allowing pilots to cover greater distances without frequent refueling stops.

Reliability stands out as a key benefit as well. Rotax engines are known for their robust construction and dependable operation, which instills confidence in pilots during flights.

Additionally, maintenance requirements tend to be straightforward. This simplicity not only reduces downtime but also results in cost savings over time.

Versatility can’t be overlooked either; Rotax engines power various aircraft types—from ultralights to light sport airplanes—making them a favorite among diverse aviation enthusiasts. Their adaptability ensures that there’s a suitable option for almost any flying need or preference.

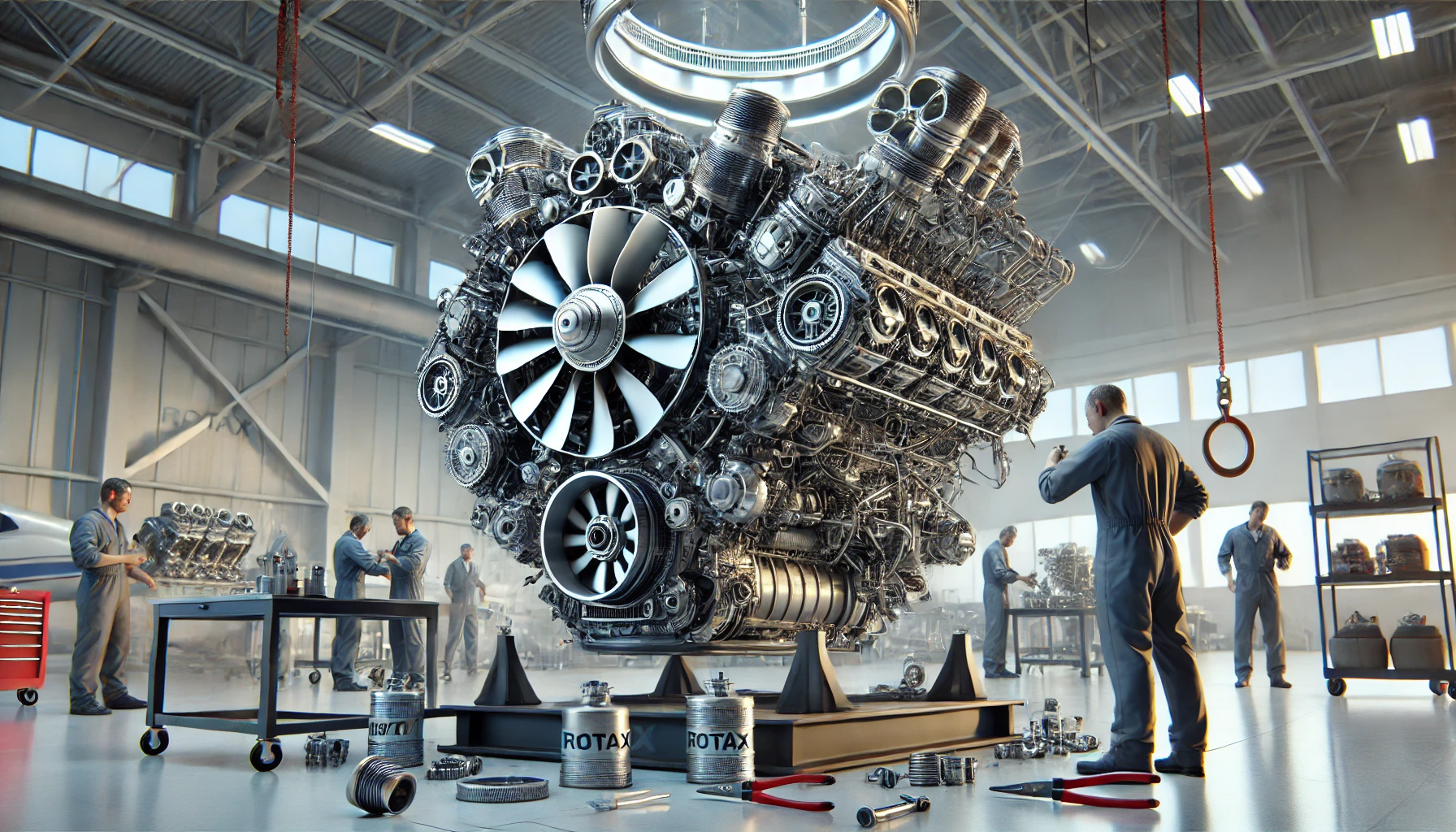

Maintenance and care for Rotax engines

Proper maintenance is crucial for the longevity of a Rotax engine. Regular inspections can help identify issues before they escalate.

Check fluid levels frequently, including oil and coolant. Maintaining correct levels ensures optimal performance.

Cleaning air filters is essential too. Dust and debris can restrict airflow, impacting efficiency.

Pay attention to spark plugs as well. Replacing them at recommended intervals keeps ignition smooth and reliable.

Inspecting fuel lines and connections should not be overlooked either. Any leaks or wear can lead to serious problems down the line.

Lastly, always consult your engine manual for specific maintenance schedules and guidelines tailored to your model. Adhering to these practices creates a solid foundation for years of trouble-free operation in the air.

Common misconceptions about Rotax engines

Many people believe that Rotax engines are only suited for small aircraft and ultralights. This is a misconception. These engines have proven their versatility in various applications, from light sport planes to larger aircraft.

Another myth is that Rotax engines lack power compared to traditional piston engines. In reality, they offer impressive performance with high power-to-weight ratios, making them an excellent choice for many flying machines.

Some also think Rotax engines are difficult to maintain. Conversely, these engines feature user-friendly designs and straightforward maintenance schedules, which contribute to their popularity among pilots and mechanics alike.

There’s also confusion about fuel types. While some assume that all Rotax models require premium fuels, many can efficiently run on mogas or even unleaded options without sacrificing performance.

Future innovations and advancements for Rotax engines

The future of Rotax engines is bright, with ongoing innovations that promise to enhance performance and efficiency. Engineers are exploring advanced materials that could reduce weight while increasing durability.

In addition, there’s a growing focus on hybrid technology. This aims to integrate electric power with traditional combustion methods, paving the way for quieter and more environmentally friendly flight options.

Enhancements in digital technologies also play a crucial role. Smart diagnostics and real-time monitoring systems can help pilots track engine health effortlessly, allowing for proactive maintenance interventions.

Moreover, sustainability is becoming a core element of development strategies at Rotax. Research into biofuels and alternative energy sources is underway to ensure these engines meet future environmental standards without sacrificing performance.

As aviation evolves, so does the commitment to pushing the boundaries of what Rotax engines can achieve in various flight applications.

Conclusion: Why Rotax engines are a top choice for powering flight machines.

Rotax engines have carved out a niche in the aviation world that is hard to overlook. Their innovative design and engineering excellence provide unmatched reliability and performance for various flight machines. Whether it’s light sport aircraft, ultralights, or experimental planes, Rotax engines deliver an ideal blend of power-to-weight ratio and fuel efficiency.

The history of Rotax showcases their commitment to growth and adaptation within the industry. Over decades, they’ve refined their technology to meet changing demands while maintaining quality.

Moreover, users appreciate the straightforward maintenance process associated with these engines. With proper care, a Rotax engine can offer years of dependable service without excessive downtime.

As advancements continue in aerodynamics and materials science, we can expect Rotax to stay at the forefront of innovation. This ensures pilots will experience even greater capabilities from their favorite flight machines powered by these exceptional engines.

Choosing a Rotax engine means opting for performance backed by decades of expertise—making them an outstanding choice for aviators around the globe. The legacy continues as more enthusiasts discover what makes these engines truly remarkable in today’s aviation landscape.